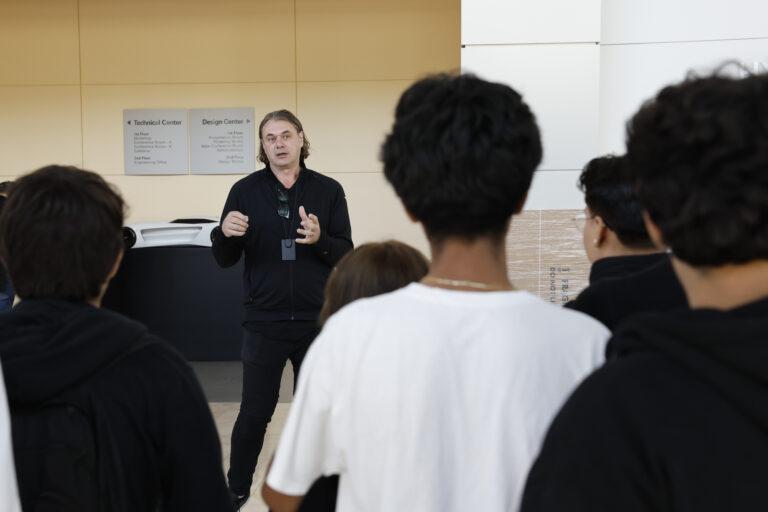

In a bold move towards efficiency and innovation, BMW Group Plant Regensburg is leading the way in transforming vehicle assembly through the integration of artificial intelligence (AI). At the core of this transformation is a state-of-the-art smart analysis system designed to prevent unplanned stoppages and streamline production processes. The proactive nature of predictive maintenance, powered by AI, is proving to be a game-changer in maintaining optimal vehicle production flow.

The assembly process at BMW Group Plant Regensburg involves vehicles attached to mobile load carriers or skid systems, navigating production halls seamlessly. Any technical glitch in the conveyor systems could disrupt assembly lines, leading to increased maintenance efforts and associated costs. To address this challenge, the innovation team at the Regensburg plant has engineered a smart monitoring system that identifies potential defects early on, avoiding any lost production time.

What sets this system apart is its reliance on AI for data-driven analyses without the need for additional sensors or hardware. By leveraging existing data from installed components and conveyor element control, the system can proactively detect anomalies and issue alerts. This enables the removal and repair of affected conveyor elements away from the production line, ensuring minimal disruption and optimal efficiency.

The success story unfolds in the numbers – the AI-supported system at BMW Group Plant Regensburg has prevented an average of around 500 minutes of disruption per year in vehicle assembly. This tangible impact underscores the transformative potential of AI in preventive maintenance within the manufacturing landscape.

As industries embrace AI-driven solutions, BMW’s journey in smart maintenance serves as an inspiration for others. The ripple effect of this innovative approach prompts us to ponder: How can AI redefine efficiency and productivity in various industrial sectors?

Photo: BMW

Source: LULOP

+ There are no comments

Add yours